Techtest Soldering Iron with Temperature Control is a compact designed soldering iron ideal for mobile phone repairing and other professional use. Hand Soldering can be performed and adjusted from the control knob from 200°C – 450°C. Interchangeable iron plated tips are available to make the soldering iron excellent for soldering electronic components and electric use.

TECHTEST Soldering Iron with Temperature Control Features

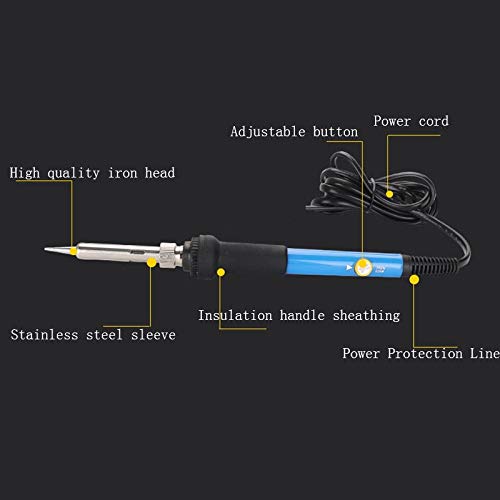

- Durable and Long Life: Adopt imported SMD PTC chip, heating fast and steady. Handle comes with rubber protective case, non-slip, high temperature resistance, effective heat insulation.

- Adjustable Temperature with Button: Temperature range is 200-450 Degree Centigrade / 392-752 Degrees Fahrenheit, Built-in temperature control button on the handle, adjust temperature according to your need.

- Energy Saving: Stainless steel soldering iron tip and pipe sleeve, fast heat conduction, strong recovery, energy saving, can use long life.

- Safe to Use: 85-265V voltage and EU/US plug, copper cable keep more safety when you work.

- Wide Application: Suitable for repairing smartphone, tablet, radio, computer, laptop, welding connector, line production in the factory.

TECHTEST Soldering Iron with Temperature Control Specification

- Temperature Range: 200°C – 450°C.

- Interchangeable iron plated tips.

- Soldering Iron Length: 18.5 cm

- Cable Length: 143 cm

- Working Voltage: 220V 50HZ

- Power: 60W

- Length of cable: 1.5m

- Packaging List: 1 x Soldering Iron 5 x Iron Tips ( I / B / K / 3C / 2.4D )

How to Solder – Step By Step Instruction

- Make sure your Techtest Soldering Iron is hot. Do not touch it.

- Hold the soldering iron properly in one hand and solder wire in the other hand. Maintain proper angle between the two. Try to use a solder wire reel stand.

- Place the solder wire at the point where the lead of the electronic components meets the copper track on the PCB.

- Apply heat at the point where solder wire touches the lead of the component.

- Once solder wire melts and soldering is done, remove the soldering iron.

- Allow few seconds to cool.

- Cut extra leads of the electronic components.

NOTE: A good solder joint should look shiny. Dull joint suggests something is wrong. If you are doing lead-free soldering, the joint will look dull in any case.

Reviews

There are no reviews yet.